From Concept to Final Product: Complete Electronics Product Design Support

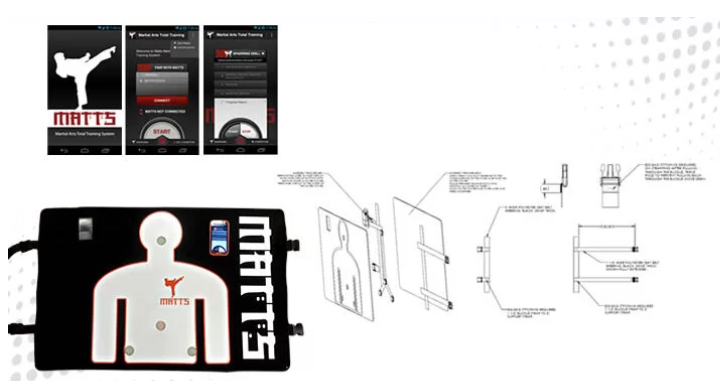

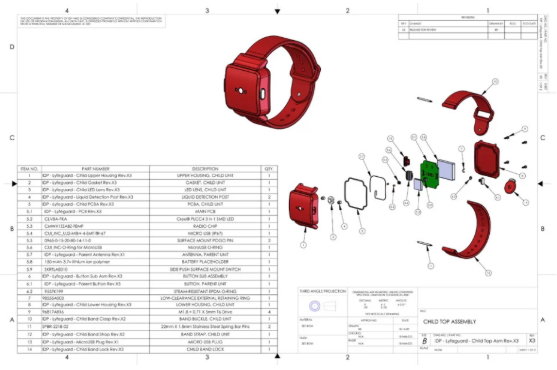

Behind every successful electronic device is a robust electronics product design process. At IDP, we bring together expert design engineers, experienced 3D modelers, skilled product developers, and cross-disciplinary specialists in electronic engineering, mechanical design, and electrical engineering to transform ideas into production-ready innovations. Our approach also integrates market research at early stages to ensure every concept aligns with customer needs and industry demand, reducing risks and increasing the likelihood of commercial success.

Whether you’re working with a rough product concept, a refined proof of concept, or starting from scratch, we guide you through each step—design, development, testing, and scaling. Our proven approach integrates key stages of the electronic product development process, including PCB design, PCB layout, and design for manufacturing (DFM). From selecting the right electronic components and designing printed circuit boards to integrating modern electronic systems and integrated circuits, we ensure that your product delivers reliable functionalities and seamless performance. Our industrial designers and engineers work together to balance aesthetics with technical precision, while comprehensive product testing guarantees that your electronics product design is not only innovative and user-friendly but also prepared for mass production without compromise.

With deep roots in the history of electronic systems—from vacuum tubes to the integrated circuit, from early electronic computers to today’s smart and connected devices—we provide a design and engineering framework that blends timeless fundamentals with modern agility.

We’ve refined our process to handle every detail:

- Smart, manufacturable product design

- User-centric electronics product design

- Expert-led electronic design engineering with scalable results

- Efficient, iterative development from prototype to final product

Compliance & Certification: Ensuring Safety and Reliability

At IDP, every electronics product development project integrates global compliance standards to guarantee safety, reliability, and regulatory approval. By embedding compliance early in the process, we help your product move smoothly from prototype to market-ready device.

Our Certifications and Standards Include:

- UL Certification – Verifies product safety and electrical compliance for consumer, wearable, and industrial electronics.

- IEC Standards – Ensures electrical, functional, and safety compliance for global markets.

- ISO Standards (ISO 9001 / ISO 13485) – Provides frameworks for quality management, design controls, and production best practices.

By combining electronic design engineering, PCB layout expertise, and electronics prototyping with rigorous compliance checks, IDP reduces risk, accelerates approvals, and guarantees your product meets the highest standards.

Standard Electronic Design vs. IDP Approach

Here’s why IDP’s full-spectrum approach to electronics product development outperforms standard design methods:

| Feature |

Standard Product Development |

IDP Electronics Product Development |

| Concept Validation |

Limited feasibility checks |

In-depth technical feasibility + market alignment |

| Design |

Basic circuits & enclosure |

PCB layout, embedded systems, industrial & ergonomic design integration |

| Prototyping |

Single iteration |

Rapid and functional electronics prototyping with iterative testing |

| Compliance |

Minimal guidance |

UL, IEC, ISO-certified processes integrated from the start |

| Manufacturing Readiness |

After design completion |

Design for manufacturing (DFM) principles, vendor selection & production ramp-up |

| Post-Launch Support |

Limited |

Continuous updates, iterations, and reliability monitoring |

With IoT electronics, embedded systems design, and electronic device engineering embedded throughout, IDP ensures your product is market-ready, safe, and scalable—faster than traditional approaches.

Quick Steps to Get Started with Electronics Product Development

Ready to transform your idea into a market-ready electronic device? IDP makes it simple:

- Share Your Concept – Tell us about your electronics product idea and goals.

- Feasibility Analysis – We assess technical, market, and compliance feasibility early.

- Prototyping & Iteration – Rapid electronics prototyping, PCB layout, embedded systems integration, and iterative testing.

- Design Validation & Compliance – Ensure your product meets UL, IEC, ISO, and industry-specific standards.

- Manufacturing Readiness & Launch – Apply DFM principles, select vendors, scale production, and support post-launch iterations.

By following this streamlined framework, IDP helps startups, innovators, and enterprises reduce risk, cut time-to-market, and deliver electronics products that are reliable, functional, and scalable.