The world of healthcare is evolving rapidly, with technology pushing the boundaries of what’s possible in diagnostics, treatment, and patient care. At the core of this transformation is medical device prototyping, an essential process that shapes innovative ideas into life-saving products. This blog explores key trends in medical device design, medical device engineering, and medical product development, shedding light on how the future is being shaped by cutting-edge advancements in design for medical devices.

The Importance of Medical Device Prototyping

A medical device prototype is a critical early-stage version of a device used for testing, validation, and refinement. It enables:

- Functional verification

- Regulatory compliance evaluation

- Feedback from clinicians and users

- Faster time-to-market

In modern medical device engineering, the ability to test before full-scale production ensures higher safety and efficacy. Companies that prioritize medical product development through prototyping significantly reduce risks and improve design outcomes.

Trend 1: Rapid Prototyping with 3D Printing

One of the most transformative innovations in medical device design is the use of 3D printing. It allows:

- Custom-fit prosthetics

- Anatomically accurate surgical guides

- Fast iterations of designs

- Cost-effective small-batch production

As 3D printing matures, its integration with medical device prototype creation is becoming standard practice. Engineers can quickly test materials, geometries, and components, enhancing design for medical devices.

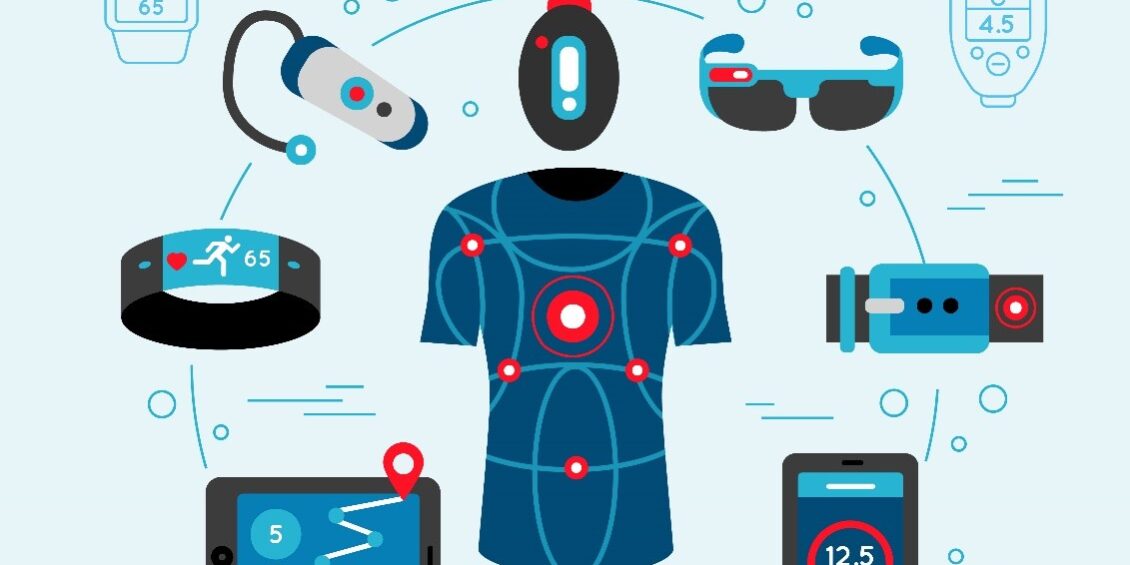

Trend 2: Miniaturization and Wearable Health Tech

Advances in microelectronics are enabling ultra-small, wearable medical devices. Prototyping these requires:

- Precision in medical device design

- Expertise in medical devices engineering

- Focus on ergonomics and power efficiency

Examples include:

- Wearable ECG monitors

- Glucose sensors

- Portable infusion pumps

Each device undergoes intensive medical product development involving multiple prototype versions.

Trend 3: Integration of AI and IoT

Smart devices powered by AI and connected via the Internet of Things (IoT) are redefining healthcare. These innovations impact medical device prototype creation in the following ways:

- Inclusion of real-time data processing capabilities

- Requirement for cybersecurity features

- Integration with cloud-based health systems

AI-driven medical device design must accommodate machine learning components and intelligent diagnostics, shaping the future of design for medical devices.

Trend 4: Human-Centered Design and Usability

Modern medical product development emphasizes user experience. Devices must be intuitive for both patients and healthcare providers. Key practices include:

- Conducting user trials early in the prototyping phase

- Ergonomic testing

- Multidisciplinary collaboration (engineers, designers, clinicians)

This shift requires medical device engineering teams to adopt a holistic view of the product’s environment and interaction points.

Trend 5: Virtual Prototyping and Simulation

Simulation tools are helping engineers visualize and test medical device prototype concepts before physical production. Benefits include:

- Reduced costs

- Accelerated development timelines

- Early identification of design flaws

Virtual simulation platforms also enhance design for medical devices by enabling real-world scenario modeling, stress analysis, and material testing.

Trend 6: Regulatory-Driven Innovation

Compliance remains a crucial part of medical device design. Trends include:

- Designing prototypes that align with FDA and EU MDR standards

- Early engagement with regulatory consultants

Ensuring that medical device engineering meets global compliance from the prototyping stage can save time and money during medical product development.

Trend 7: Sustainable and Eco-Friendly Design

Sustainability is entering the realm of medical device prototype development. Engineers are exploring:

- Recyclable and biodegradable materials

- Energy-efficient electronics

- Reusable components

Medical product development teams now factor in end-of-life strategies to reduce waste and environmental impact.

Trend 8: Personalized and Precision Medicine Devices

Personalization is changing the way we approach medical device design. Prototypes are being tailored to individual:

- Anatomies

- Treatment plans

- Genetic profiles

This requires advanced design for medical devices techniques, data integration, and cross-disciplinary collaboration in medical device engineering.

Case Study: A Startup’s Journey in Medical Device Prototyping

A startup aimed to develop a smart inhaler that tracks dosage and user behavior. Their prototyping journey could include:

- 3D printed housings for ergonomics

- Integration of sensors via IoT

- Collaboration with pulmonologists

- Clinical trials using the medical device prototype

Their success was grounded in iterative medical product development and a patient-centered approach to medical device design.

Looking Ahead

As healthcare becomes increasingly digital, the future of medical device design will depend on:

- Integration with telehealth platforms

- AI-assisted diagnostics

- Global collaboration on innovation

In this landscape, a robust medical device prototype process is more vital than ever. Organizations that adopt agile, user-focused design for medical devices and leverage evolving tech will lead the market.

Conclusion

The future of healthcare innovation lies in the seamless convergence of technology and design. With trends like 3D printing, AI, and sustainability driving change, medical device engineering must evolve to create prototypes that are smart, safe, and scalable. By embracing cutting-edge tools, specialized prototype development services, and user-centric strategies, today’s innovators can ensure that their medical product development journey leads to devices that transform lives. Now more than ever, knowing how to prototype effectively and iterate efficiently in medical device design will determine the success of next-generation healthcare solutions.

Got an idea? Let’s turn it into a market-ready product.

At IDP, we help startups and businesses design smarter, build faster, and confidently launch. From concept to prototype to full-scale production—our experts are here to guide you every step of the way.

Ready to build it right the first time?

Let’s connect at https://innovativedesignproducts.com/get-started/ or call Holly Grantham or Jennifer Rivkind at 949.748.1902 to discuss your project and obtain a full explanation of our development process.